Standards and regulations for hose whip restraints

In our years of experience, the products that are most often ordered with urgent delivery are hose safety whip checks and nylon hose whip restraints. It is no wonder based on how many agencies and organizations require their use. Various agencies word their regulations differently, but primarily they all come to the same requirement: If a hose connection is pressurized, and can cause a hazardous condition, then you must install a hose safety restraint. While we stress to always err on the side of safety, lets look at some of these codes and regulations:

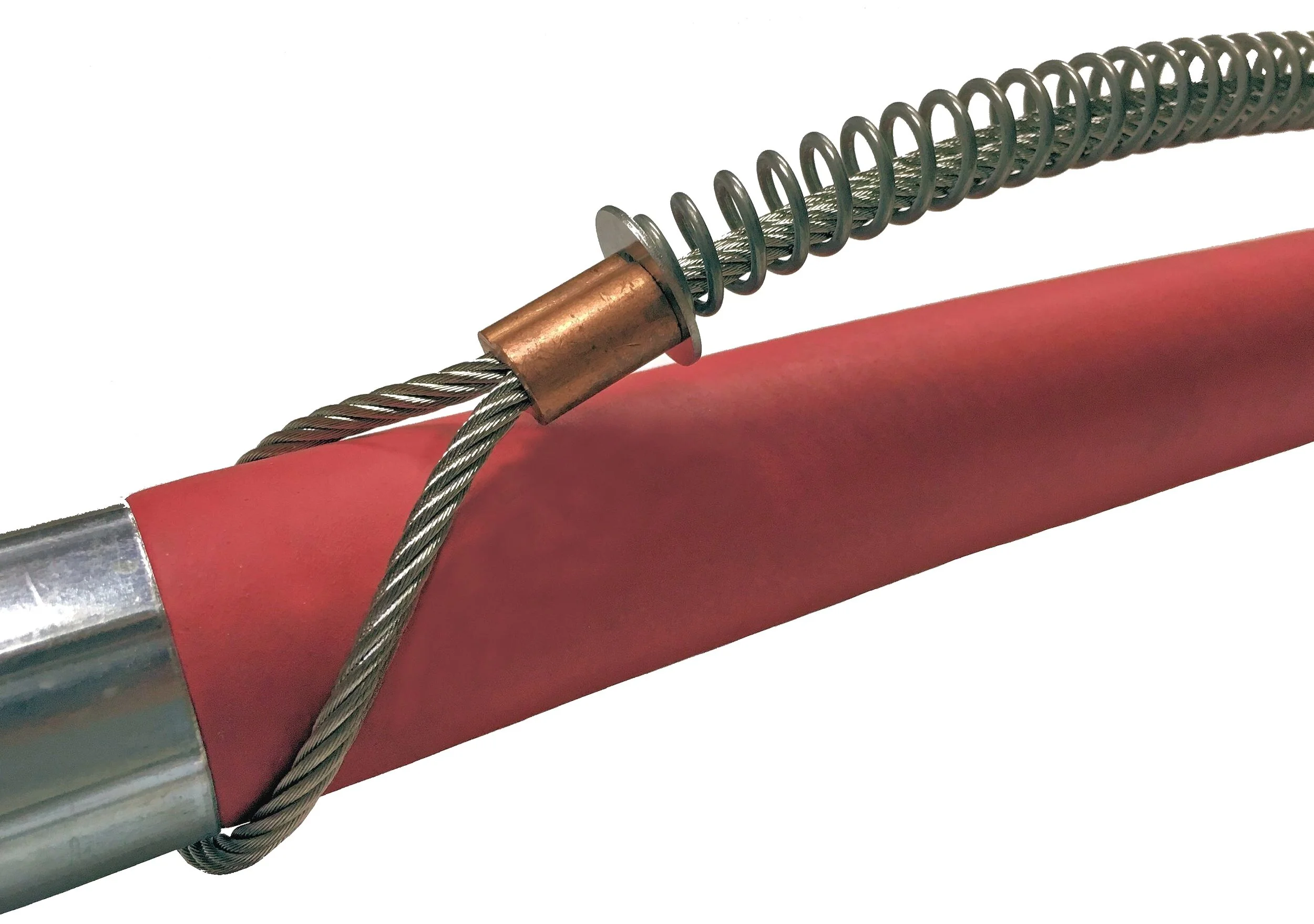

OSHA 29 CFR 1926.603 paragraph (a)(10): Safety chains, or equivalent means, shall be provided for each hose connection to prevent the line from thrashing around in case the coupling becomes disconnected.

This falls under pile driving equipment, in particular for steam hammers, but can also be used as an example for hoses conveying other pressurized fluids or gases.

OSHA 29 CFR 1926.302(b) (1): Pneumatic power tools shall be secured to the hose or whip by some positive means to prevent the tool from becoming accidentally disconnected. Additionally 1926.302(b) (7) states: All hoses exceeding ½-inch inside diameter shall have a safety device at the source of supply or branch line to reduce pressure in case of hose failure.

This falls under Pneumatic power tools (from Subpart I Tools — Hand and Power). In this regulation, the hose or "whip" would be a short whip hose permanently attached to the tool, not a whip check. 'Positive means' may also be interpreted as a locking sleeve retractable quick disconnect coupling, however it is still recommended that a whip check or nylon restraint be installed when possible to further minimize risk.

Access complete above referenced statement here

The valve referenced in CFR 1926.302(b)(1) is designed to be installed at the source such as the beginning of all branch lines off of a manifold, receiver tank, or compressor. Also note: 1910.169(b)(3)(ii) and 1926.306(b) (3) (ii) No valve of any type shall be placed between the air receiver and its safety valve or valves. Install ball valves after the check valve, not between the check valve and the source!

Also note the following statement: 'We emphasize that the above list of provisions is not a comprehensive list of OSHA construction standards that may apply to the use of your hand tool. As you know, when tools are used in construction applications, they must comply with all applicable 29 CFR Part 1926 requirements. Keep in mind that the applicability of OSHA construction standards is often keyed to a particular activity rather than simply to a type of equipment.'

Access complete above referenced statement here

MSHA 30 CFR 56/57.13021 High Pressure Hose Connections

Except where automatic shutoff valves are used, safety chains or other suitable locking devices shall be used at connections to machines of high-pressure hose lines of ¾-inch inside diameter or larger, and between high-pressure hose lines of ¾-inch inside diameter or larger, where a connection failure would create a hazard. -This standard requires the use of safety chains or other suitable locking devices at certain high-pressure hose-to-hose or hose-to- machine connections. Quick-coupling connectors are considered to be in compliance with this standard without safety chains or other locking devices if the wire used to hold the connectors is actually in use.MSHA 30 CFR §75.1730 this article restates the above regulation but under Compressed air; general; compressed air systems. It does note that high pressure is defined as 100 PSI or greater.

Regulations from other agencies:

US Army Corps of Engineers: 13.G.02 Connections and nozzles shall be designed to prevent accidental disengagement. All connections shall be equipped with safety lashings. 20.A.17 Connections with high pressure hoses must be secured with a safety lashing/whip check.

Canadian Centre for Occupational Health & Safety: Make sure that hose connections fit properly and are equipped with a mechanical means of securing the connection (e.g., chain, wire, or positive locking device).

US Bureau of Reclamation 17.2.2 Air Hoses: For air lines more than one-half inch inside diameter, provide whip-check devices attached to the hose at each connection or splice. As a substitute, provide a safety device at the source of supply or branch line that will automatically reduce pressure in case of a line failure if the device effectively prevents whipping.

CDC National Institute of Occupational Safety and Health: Good practice recommends that hoses longer than 3 feet should have secondary restraint if they are: High pressure high volume hoses (Rotary hoses, vibrating hoses, cement hoses, circulating hoses), Compressed gas hoses (air hoses ¾” and larger, nitrogen transfer / service hoses), Energized fluid lines (steam hoses, water blasting, test pump lines).

As you can see, there are many similar regulations in place across a number of agencies. While some have differing opinions on minimum size or pressure, all make the recommendation or requirement that hose safety devices and valves are an integral part of protection and risk mitigation. Install these wherever possible, and train operators in their proper installation.

We have gathered these standards and regulations from source material found online and make no guarantee that they are current or complete. Please check directly with any regulating agencies that may oversee your workplace to ensure compliance.